The sealing performance of O-ring is excellent and its working life is high. The working life of dynamic pressure seal is 5-10 times higher than that of conventional rubber seal products, and the maximum is dozens of times. Under some conditions, it can have the same life with the sealing matrix.

The friction resistance of O-ring is small, and the dynamic and static friction are equal. It is 1 / 2-1 / 4 of the friction of "0" rubber ring, which can eliminate the "crawling" phenomenon of low-speed and low-pressure movement.

The O-ring is highly wear-resistant and has the function of automatic elastic compensation after the sealing surface is worn.

O-ring has good self-lubricating performance and can be used as oil-free lubrication seal.

The O-ring has simple structure and convenient installation.

Working pressure of O-ring: 0-300mpa; working speed: ≤ 15m / S; working temperature: - 55-250 ℃.

Applicable media of O-ring: hydraulic oil, gas, water, mud, crude oil, emulsion, water glycol, acid.

The O-ring is suitable for installation on various mechanical equipment, and plays a sealing role in static or moving state in the specified temperature, pressure, and different liquid and gas media. In machine tools, ships, automobiles, aerospace equipment, metallurgical machinery, chemical machinery, engineering machinery, construction machinery, mining machinery, petroleum machinery, plastic machinery, agricultural machinery, as well as various instruments and meters, a large number of types of sealing elements are applied. O-ring is mainly used for static seal and reciprocating seal. When it is used for rotary motion seal, it is only limited to the low-speed rotary seal device. O-ring is generally installed in the groove with rectangular section on the outer circle or inner circle to seal. O-ring still plays a good role in oil, acid and alkali resistance, grinding, chemical erosion and other environments. Therefore, O-ring is the most widely used seal in hydraulic and pneumatic transmission system.

Compared with other sealing rings, O-ring has the following advantages:

--Suitable for a variety of sealing forms: static sealing and dynamic sealing

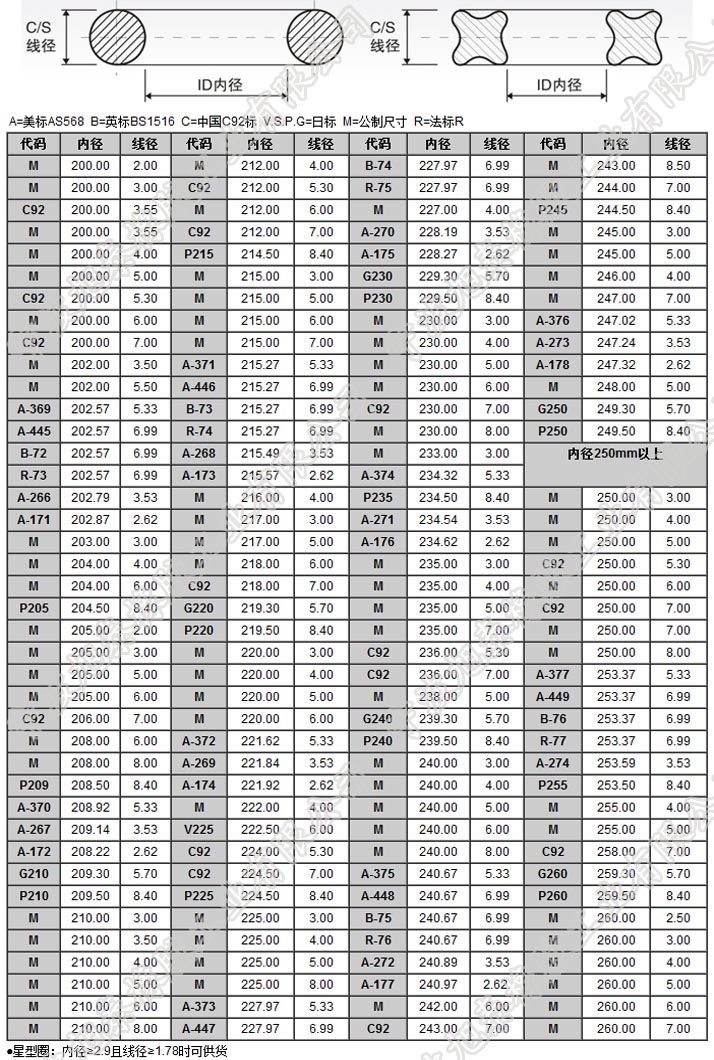

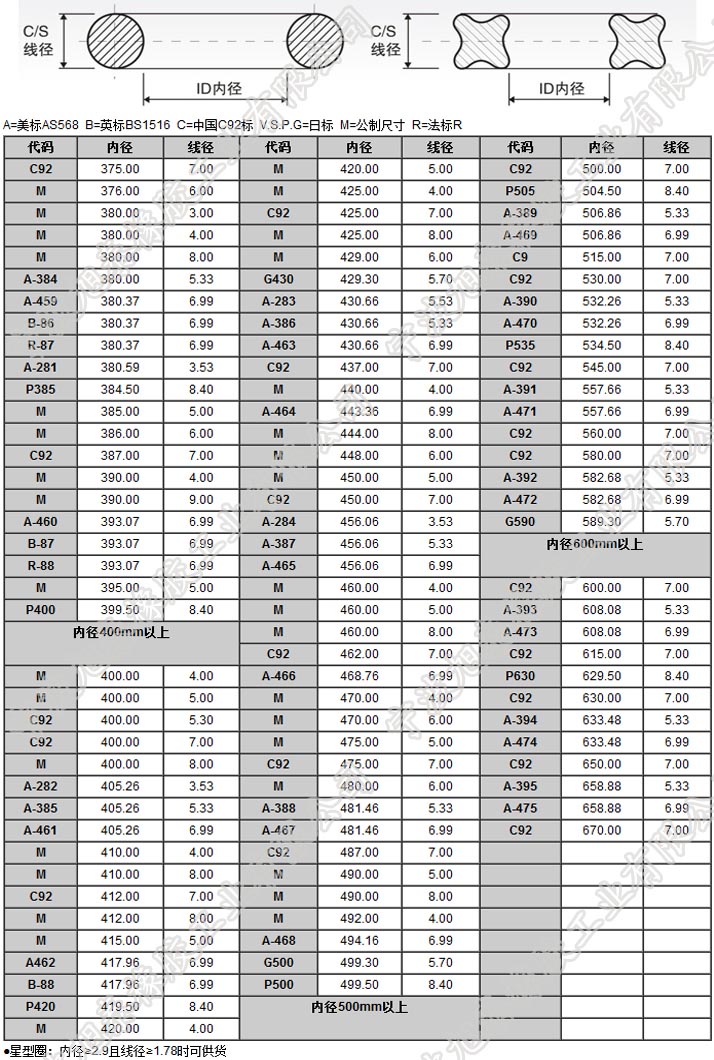

--It is suitable for all kinds of materials, and its size and groove are standardized, with strong interchangeability

--Suitable for multiple motion modes: rotary motion, axial reciprocating motion or combined motion (such as rotary reciprocating combined motion)

--Suitable for a variety of different sealing media: oil, water, gas, chemical media or other mixed media

--By choosing the right rubber material and the right formula design, it can effectively seal oil, water, air, gas and various chemical media. The temperature range is wide (- 60 ℃ ~ + 220 ℃), and the fixed pressure can reach 1500kg / cm2 (used together with reinforcing ring).

--Simple design, small structure, easy to install and disassemble

The section structure of O-ring is very simple, and it has self sealing function and reliable sealing performance.

As the O-ring itself and its installation parts are extremely simple and standardized, it is very easy to install and replace.

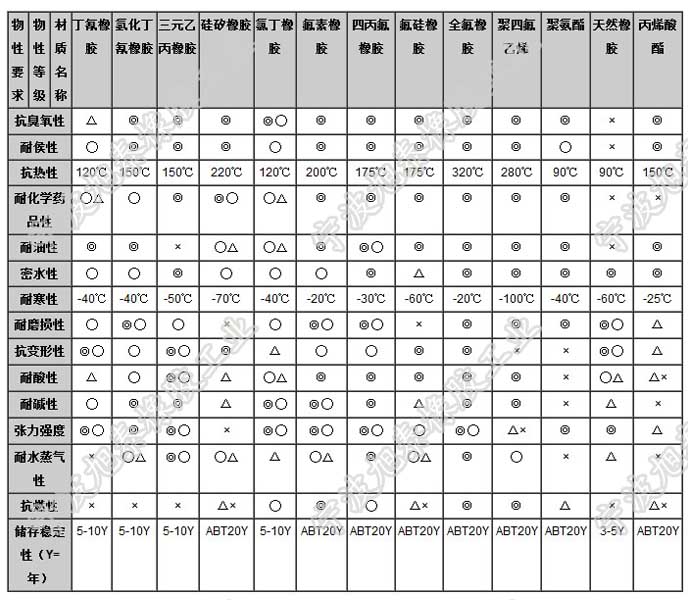

--Variety of materials

It can be selected according to different fluids: NBR, FKM, VMQ, EPDM, Cr, Bu, PTFE, NR, etc

--Low cost

--The dynamic friction resistance is relatively small

O-ring material classification comparison and advantages and disadvantages:

1. Natural Rubber NR

Natural rubber is a kind of isoprene polymer, which is made of rubber latex collected from rubber tree. It has good wear resistance, high elasticity, breaking strength and elongation. It is easy to age in the air and become sticky in case of heat. It is easy to expand and dissolve in mineral oil or gasoline. It is alkali resistant but not acid resistant. ·It is the raw material for making adhesive tape, rubber hose and rubber shoes, and is suitable for making shock absorption parts and products used in automobile brake oil, ethanol and other liquid with hydrogen peroxide.

2. SBR s b r

(styrene butadiene copolymer) the copolymerization of butadiene and styrene, compared with natural rubber, has uniform quality and less foreign matters, but its mechanical strength is weak, so it can be mixed with natural rubber.

Advantage:

--Low cost non oil resistant material

--Good water resistance, good elasticity under hardness 70

--Poor compression deflection at high hardness

--Most neutral chemicals and dry and nourishing organic ketones can be used

Disadvantages:

It is not recommended to use strong acids, ozone, oils, esters, fats and most hydrocarbons. ·It is widely used in tire industry, shoe industry, cloth industry and conveyor belt industry.

3. IIR

(butyl rubber) is polymerized from isobutylene and a small amount of isoprene, with a small amount of unsaturated base for sulfur addition. Because the movement of the three-dimensional obstacle molecules of methyl is less than that of other polymers, the gas permeability is less, the resistance to heat, sunlight and ozone is large, and the electrical insulation is good; the resistance to polar solvents such as alcohol, ketone and ester is large, and the general use temperature range is - 54 ~ 110 ℃.

Advantage:

--Impermeability to most general gases

--Good resistance to sunlight and ozone

--Can be exposed to animal or vegetable oils or oxidizing chemicals

Disadvantages:

--It can be used together with petroleum solvent, gum kerosene and aromatic hydrogen.

--It is used to make rubber parts of chemical resistant and vacuum equipment.

4. HNBR

Hydrogenate nitrile hydrogenated bunting eye glue is a kind of bunting eye glue in which part of double chains are removed after hydrogenation. After hydrogenation, its temperature resistance and weather resistance are much higher than that of normal bunting eye rubber, and its oil resistance is similar to that of normal bunting eye rubber. Generally, the temperature range is - 25 ~ 150 ℃.

Advantage:

--The butene glue has better